Ultrasonic Wire Harness Welding Machines(Professional Production and Manufacturing)

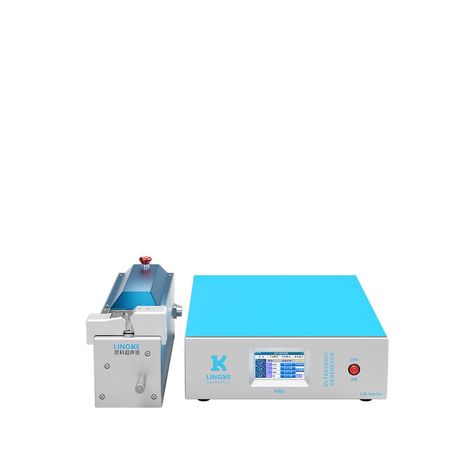

Ultrasonic Wire Harness Welder

LM300 Standard-H Model

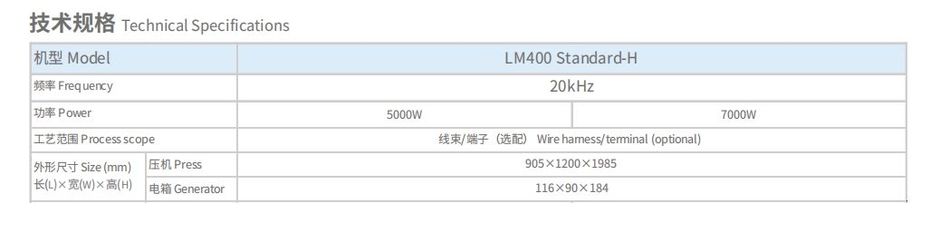

LM400 Standard-H Semi Automatic Landing Model

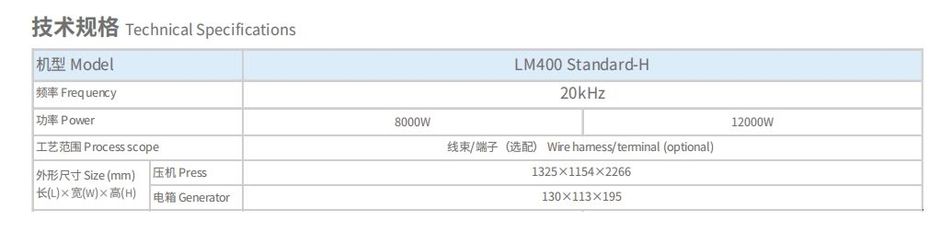

LM400 Standard-H Semi Automatic Landing Model

Features ——

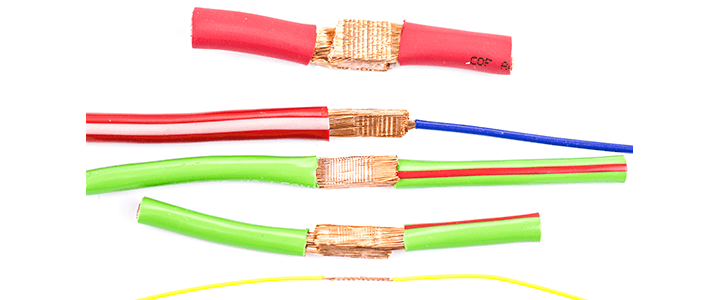

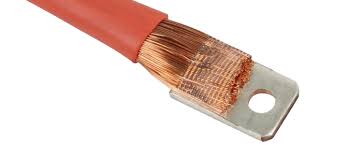

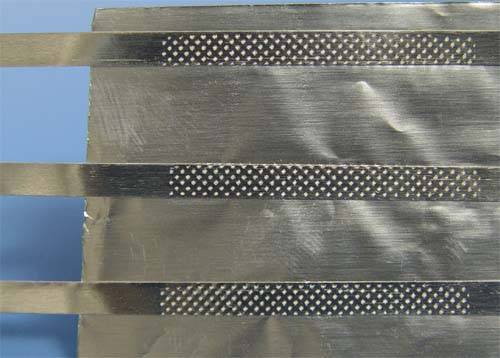

• Highly versatile, can weld wire harnesses from 0.7mm² to 30mm², up to 90mm², and up to 120mm².

• Double merging, double merging, no need to replace fixtures, can switch from.

• The time can be precise to 0.01 seconds and has a secondary ultrasonic function.

• High precision upper and lower machine head X guide rail German structure, with high mechanical performance, precision, and stability.

• Welding height protection setting, stable and reliable welding quality, firm welding, no false welding, no welding cracks.

• You can choose the model according to your needs and customize various fixtures to meet the welding needs of different square wire harnesses.

Function ——

• 4 operating modes: time mode, energy mode, manual mode, external control.

• 5 types of intelligent management: quality management, formula management, data management, safety management, and amplitude management.

• Data management: Data export/MES system with built-in storage/transfer welding data function, facilitating intelligenttracking of data.

• The wiring harness can adjust various parameters to meet various technical requirements, with fast welding speed and simple operation.

• Monitoring management: Self monitoring function, auto matic frequency tracking during operation, welding abnormality alarm, real-time monitoring of welding effect, achieving quality monitoring

• The generator monitors each set of welding parameters in real-time throughoutthe entire process to prevent welding errors. It can also be monitored online, with the function of searching for project numbers and calling welding parameters at any time.

Contact us any time

Contact Us

We will get back to you as soon as possible

Please try again later

Quick & Reliable

See In Ultrasonic Machinery is an established company, ever since its incorporation in June 2001.

Navigation

All Rights Reserved | See-In Ultrasonic Machinery

Designed by Trinity42