Ultrasonic Metal Spot Welding Machines(Professional Production and Manufacturing)

Ultrasonic Spot Welder

Power battery of Ultrasonic Metal Spot Welding Machines

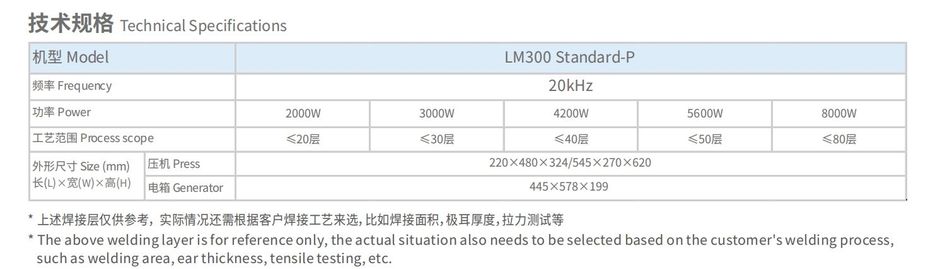

LM300 Standard-P Model

Power battery of Ultrasonic Metal Spot Welding Machines

LM300 Standard-P Model

Cylindrical Cap of Ultrasonic Metal Spot Welding Machines

LM300 Standard-P Mode

Features ——

• Using SIEMENS programmable controller, the time can be precise to milliseconds.

• Advanced constantvoltage amplitude circuittechnology, equipped with time, power, energy, etc.

• Welding is firm, the welding points are beautiful, there is no false welding,no welding cracks, no vibration or loosening of the cap explos ion-proof valve, and there is good residue acrumulation

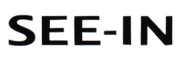

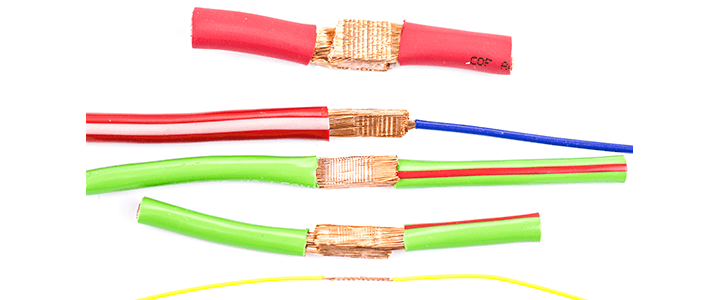

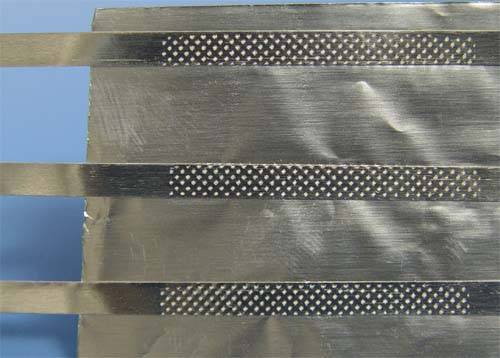

• Widely used in the welding of single-layer copper foil to nickel sheet or sin gle-layer aluminum foil to aluminum sheet, as well as the small area welding of multi-layer copper foil to nickel sheet or multi-layer aluminum foil to alum inum sheet: Pre welding of battery foil material and welding of foil material to current collector.

Function ——

• 4 operating modes: time mode, energy mode, manual mode, external control.

• Monitoring management: self-monitoring function, automatic frequency tracking during operation, welding abnormality alarm.

• 5 types of intelligent management: quality management, formula management, data management, safety management, and amplitude management.

• Diversified triggering mode ofthe electrical box, integrated welding stability system monitoring, highly monitoring welding parameters.

• Data management: Data export/MES system with built-in storage/transfer welding data function, facilitating intelligent tracking of data.

• Multi layer welding of power batteries (power soft package, power softs hell) is a highend intelligent typewith multiple PACK welding options, which can achieve largescaleone-time welding, and0.2-0.3 aluminum to 0.2-0.3copper nickel platingl welding.(Function of Cylindrical Cap of Ultrasonic Metal Spot Welding Machines LM300 Standard-P Mode)

Contact us any time

Contact Us

We will get back to you as soon as possible

Please try again later

Quick & Reliable

See In Ultrasonic Machinery is an established company, ever since its incorporation in June 2001.

Navigation

All Rights Reserved | See-In Ultrasonic Machinery

Designed by Trinity42