Ultrasonic Metal Terminal Welding Machines(Professional Production and Manufacturing)

Ultrasonic Metal Terminal Welder

Features ——

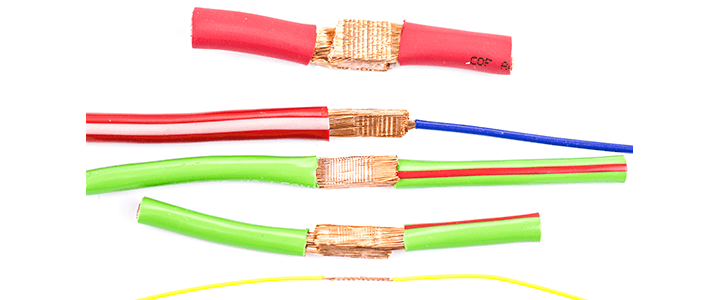

• Double merging, doublemerging, no need to replacefixtures, can switch from.

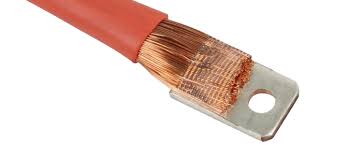

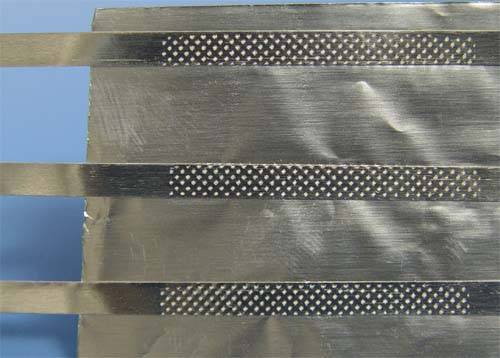

• Strong adaptability, can weld 30-90mm² Wire harness and terminal welding.

• The time can be precise to 0.01 seconds and has a secondary ultrasonic function.

• High precision upper and lower machine head X guide rail German structure, with high mechanical performance, precision, and stability.

• Adopting economical logo control and using Siemens PLC for programmable parameter settings.

• Welding height protection setting, stable and reliable welding quality, firm welding, no false welding, no welding cracks.

• You can choose the model according to yourneeds and customize various fixtures to meet the welding needs of different square wire hamesses and terminals.

Function ——

• 4 operating modes: time mode, energy mode, manual mode, external control.

• 5 types of intelligent management: quality management, formula management, data management, safety management, and amplitude management

• Data management: Data export/MES system with built-instorage/transfer welding data function, facilitating intelligent tracking of data.

• Monitoring management: Self monitoring function, automatic frequency tracking during operation, welding abnormality alam, real-time monitoring of welding effect, achieving quality monitoring.

• The generator monitors each set of welding parameters in real-timeand can be monitored online. The project number search functioncan be used to call welding parameters atany time, display welding combinationsand total welding square, and prevent welding errors.

Contact us any time

Contact Us

We will get back to you as soon as possible

Please try again later

Quick & Reliable

See In Ultrasonic Machinery is an established company, ever since its incorporation in June 2001.

Navigation

All Rights Reserved | See-In Ultrasonic Machinery

Designed by Trinity42